You know that I’m not a big promoter of new products here, but every once in a while, someone comes up with a product or technique that makes it easier and cheaper to save old houses. And when that happens, I am all over it like white on rice!

You know that I’m not a big promoter of new products here, but every once in a while, someone comes up with a product or technique that makes it easier and cheaper to save old houses. And when that happens, I am all over it like white on rice!

My company has recently become a dealer for Indow Windows. Why? Because they work! I have them in my own home and it is truly incredible how much of a difference they make in not only my utility bills but the street noise we use to get.

There are lots of exterior storm windows on the market, but unless they are historic wood storms, I feel like they make your old windows look so ugly. I know I’m not alone in this.

I found out about Indow Windows a few years ago, but was hesitant until just recently. Ultimately, there were 3 things that finally convinced me to partner with this company and I want to share them with you today because I think these windows may be the best solution to a problem we all have: Drafty windows we strangely love.

Reason #1 The Testing

I’m a facts guy. I don’t respond to crazy claims abut how awesome something is. Show me the facts and I’ll make up my own mind. Well, that’s exactly what happened here.

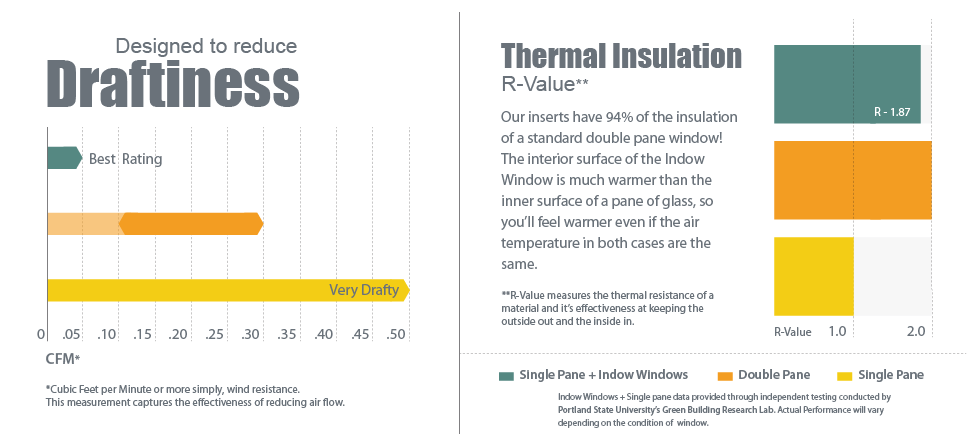

Indow Windows tested the heck out of these windows. They independently tested their efficiency again standard single-paned windows and against replacement double-paned windows. The results were jaw dropping to me!

For example, when comparing air leakage the here’s what the tests revealed:

The same round of testing also revealed that Indow Windows reduced sound transfer by 50-70% as opposed to double-paned replacement windows that reduced the sound transfer by only 20-30% over a single-paned window.

The same round of testing also revealed that Indow Windows reduced sound transfer by 50-70% as opposed to double-paned replacement windows that reduced the sound transfer by only 20-30% over a single-paned window.

Reason #2 The Company

Finally meeting Sam Pardue, the founder and CEO, face to face and hearing his story was a big reason I decided this was my kind of company.

Sam is just another old house lover, who like us, lives in an old Bungalow in Portland, OR. He got sick of the winter drafts in his old house, but didn’t want to replace his original windows. He tried several different solutions before he finally came up with the Indow Window he sells today.

A regular guy looking for a better solution to the problem that plaques all of us old housers.

Reason #3 Simplicity

As if the other reasons weren’t enough, this one clinched it for me. I’ve installed and removed lots of storm windows over the years. Lots of cutting, drilling, screwing.

They’re not terribly difficult, but it would take me a whole weekend to install standard exterior storms on my house. Not to mention the 2nd and 3rd story are a real pain to do! And then they just look so ugly anyway.

Indow Windows don’t require you to do anything but press them into place! Here’s a quick video of installation.

They are custom measured to fit each window and they are compression fit into place. 10 seconds per window! Seriously, it’s about the only thing I’ve done on my old house that is that simple.

There are no modifications or cutting of your original windows. The historic parts of your house stay right as they were.

And once they are installed, they have such a slim profile that you barely notice they are there. The house looks the same on the outside and from the inside no one will notice them unless they look very hard.

The Downside

I always want to be honest with you here at The Craftsman and there is one thing that is a negative for me with these windows. You can’t measure and order these yourself. You have to have an Indow Window dealer in your area do it for you.

I understand why, but I wish it was simpler to get them. The reason it’s like this is because every window on an old house is so different. They are often out of square and have weird dimensions so standard size storm windows won’t fit perfectly.

The dealer has to come over and take some very specific measurements with a laser and then Indow can custom make each one of your windows so that they seal perfectly.

Like I said, it makes sense so you get the best performance and don’t order windows that you have to send back, but it’s still annoying if you don’t have a dealer in your area.

That’s one of the reason’s I decided to become a dealer for the whole state of Florida. To help my state, at least, save their old windows.

If getting these windows convinces one person to save their home’s original windows then I will consider this post a huge success. Take an honest look at these windows and when you see the price, the performance and the appearance, I’ll bet you come to the same conclusion as me.

Some of the links on this page are affiliate links which means we get a small commission (at no extra cost to you!) if you decide to buy Indow Windows through our links. If you don’t want to buy through our links, you can find them at www.indowwindows.com

Founder & Editor-in-Chief

I love old houses, working with my hands, and teaching others the excitment of doing it yourself! Everything is teachable if you only give it the chance.

Scott,

Whatever happened to the Indow Window product you were promoting back in 2016? Are you still a dealer for them?

If not, do you have any other product recommendations for a very easy DIY insert window insert that can offer sound proofing?

Dave in Sanford, FL

Hi David, Thank you for your inquiry. Yes, we are still a dealer for Indow inserts. Please email my office at info@austinhistorical.com and we will send you a link where you can upload photos and measurements of your windows. Please be sure to include a photo of your sills, so we can make sure you have enough room for an Indow insert. We will send you a quote and move forward with a technical measure if you make a purchase.

how long has indow windows been in business? I also got a quote for 4 windows and it was around $2500?? Way more than I thought it would be. Also what kind of warranty of customer satisfaction gauranteed, or refund if not satisfied? Thanks Pam

Indow has been around for well over a decade and while they certainly charge premium prices for a premium product the results have been excellent in my experience. They offer a perfect fit guarantee that every insert fits or they will remake it and they offer a Lifetime residential warranty so that if any insert breaks other than due to abuse they will replace it.

At my office, I have several 160sq/ft window walls consisting of multiple panels within metal mullions… the street outside has gotten progressively worse over the years. Indow would cost between $6K and $7K for each wall…. That’s getting into the “prohibitively expensive” territory even if it can be written off as an office maintenance expense.

I saw Indow’s “How It’s Made” video on YouTube and this confirmed my suspicion there is nothing challenging or complex about the fabrication process or the materials used. The vinyl and the weather stripping can be ordered from McMaster-Carr and this would be a simple and likely enjoyable DIY project at an estimated cost of $8sqft (before the cost of shipping is factored in!).

Thoughts (because typing it out helps me plan it):

1. I’m thinking 3/16 thickness is perfect for price/performance. Their website notes their acoustic grade is 1/4″ thick and their standard grade is 1/8″ thick. I would think 1/8 would bow on larger windows and 1/4″ would be too heavy.

2. I think the weather seal “bulb” is 3/4″ diameter by visual estimate in the youtube video. Their “compression tubing” is noted as patented on their website, so this is a major concern… but I think you can get away with a generic buy-out item. Here is the product link https://www.mcmaster.com/1120a592. I would cut the windows to allow 1/2 compression of the bulb. So window dimension -3/4″ top and bottom.

3. And at the bottom compression tubing, it will surely be crushed by the weight of the vinyl over time so I’m thinking of filling the hollow bulb with something. A 48×96 sheet of this stuff will weight approx 40 lbs. So I’m thinking about sliding in a 3/8″ round wooden dowel to limit the bottom to 1/2 compression.

Any thoughts… ideas? I have major concerns about the “compression tubing” and the ability to make a safe and snug tight fitting into the window frame. I wouldn’t want one of these frames to fall out and injure someone. Maybe 1/2 compression is not enough… maybe 3/4 compression? Maybe I will run a bead of gorilla glue on the top window compression tube to fix it into place?

Mike, did you ever get a chance to try your idea? If so, how did it go?

Are these available in North Carolina? Would they work on our single pane metal casement windows?

Available nationwide and they do work on steel casements.

Hi Scott, How have these Windows held up after regularly taking them down during warm seasons when not needed and in cold seasons when they get reinserted. Do they maintain a seal? Do they still properly fit? Are there issues with opening and closing windows when indow is removed. Thanks, Tony

I have 5 Window that measure Height 57 3/4 ” width 34″ could you give an estimate as to cost